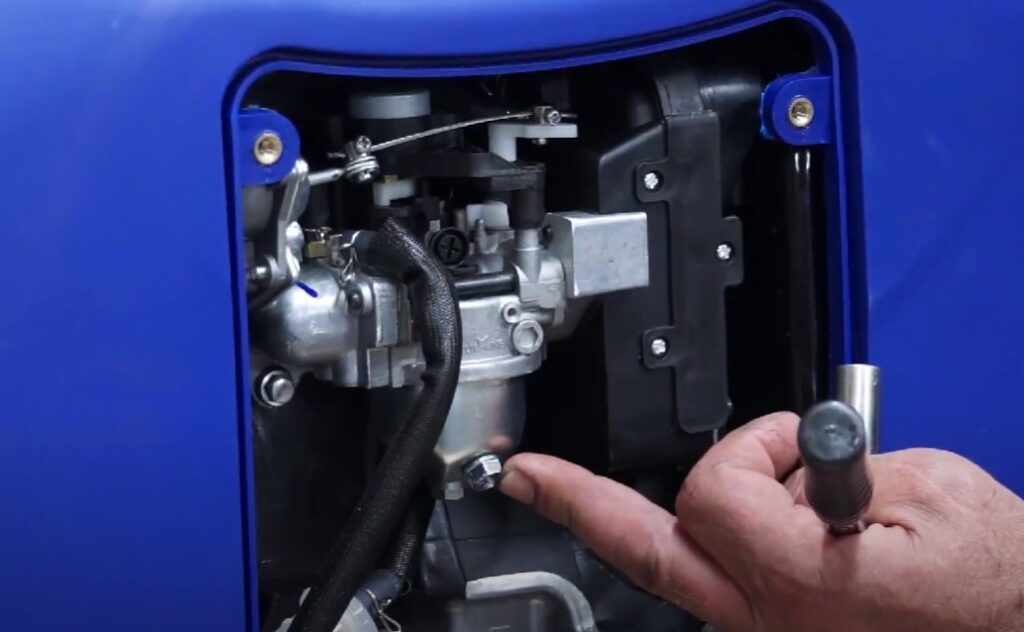

A generator carburetor is a crucial component that controls the mix of air and gasoline in an internal combustion engine. This mixture is essential for the engine to function correctly, and any imbalance could lead to significant operational issues. Regular carburetor maintenance ensures your generator is ready to operate optimally when needed.

Common Causes of Carburetor Issues

- Old or Contaminated Fuel: Gasoline can degrade over time and may cause varnish deposits that clog the carburetor.

- Debris and Dirt: Dust, dirt, or tiny particles can infiltrate the carburetor, causing it to malfunction.

- Wear and Tear: Over time and with regular usage, the carburetor’s components can wear out.

- Inadequate Maintenance: Infrequent cleaning and lack of servicing can lead to numerous carburetor problems.

Signs of Carburetor Problems

- Difficulty Starting the Generator: A carburetor issue can prevent the generator from starting or cause hard starts.

- Inconsistent Power Output: The generator might run rough or inconsistently if the carburetor isn’t functioning properly.

- High Fuel Consumption: A malfunctioning carburetor may not regulate fuel correctly, leading to excessive consumption.

- Engine Backfire or Overheating: These could be signs of a faulty carburetor.

- Detailed Breakdown of Common Carburetor Problems

Generator Carburetor Problems Detailed Discussion

Clogged Jets

- Causes: The buildup of old gasoline or debris can clog the jets.

- Symptoms: The engine might run lean (too much air, not enough fuel), leading to inefficiencies or overheating.

- Solutions: Regular cleaning or replacement of the jets can alleviate this problem.

Worn or Damaged Needle Valve

- Causes: The needle valve can wear down or become damaged over time.

- Symptoms: The engine may flood due to too much fuel being allowed into the carburetor.

- Solutions: Replacing the needle valve can restore proper fuel flow.

Float Malfunction

- Causes: A damaged float or incorrect float level can cause problems.

- Symptoms: Incorrect fuel levels can cause the engine to run rich (too much fuel, not enough air) or lean.

- Solutions: Adjusting the float level or replacing a faulty float can resolve these issues.

Blocked Passageways

- Causes: Debris or deposits can block the tiny passageways in the carburetor.

- Symptoms: The generator might have a hard start, run inefficiently, or consume too much fuel.

- Solutions: Cleaning the passages can help solve these issues.

How to Prevent Generator Carburetor Problems

Preventing carburetor problems begins with regular cleaning and maintenance. Also, use fresh fuel and do not leave fuel in the generator for extended periods. Proper generator storage can prevent dust and debris from entering the carburetor. Regular professional inspections are also advisable to catch and fix minor issues before they turn into significant problems.

Conclusion

The generator carburetor is a vital component that requires regular attention and maintenance to function effectively. Always look for common signs of problems to fix them early. Remember, prevention is better than the cure.

Related Post:

Recent Posts

Yes, synthetic oil can generally be used in generators. It offers superior lubrication, improved resistance to temperature variations, and longevity compared to conventional oil, which can enhance...

In today's digital age, our dependency on computers and other electronic devices is undeniable. But what happens when a power outage occurs? This is where generators come in. However, is it safe to...